The Mug

The only mug you'll want to use every single day.

The Mug

The only mug you'll want to use every single day.

Design

Hold it, and you’ll get it. The Mug’s soothing hand-feel, durable construction, and grounding color palette make it the one you’ll reach for again and again. You might want to buy a few, so you’re never without. Or, squirrel them away for last minute gift-giving. It’s a true MVP that has all the stamina and charisma to play for years to come.

Pair with the Brewing Basket! It fits perfectly inside The Mug.

Details

- Dishwasher and microwave safe

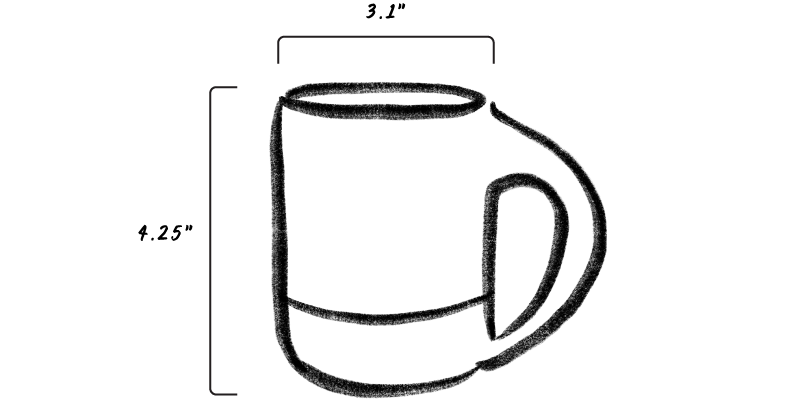

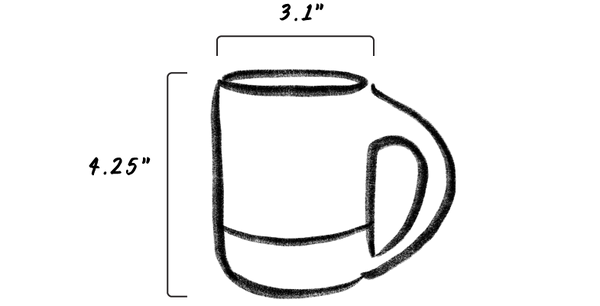

- Dimensions: 4.25" x 3.1"; Weight: 16 oz

- Holds: 12 oz to the brim, 10 oz comfortably

- Fits an Aeropress

- 100% lead-free and made from regional materials

- Our pottery is made by humans in Asheville, North Carolina. Any differences in glaze applications and surfaces are there to embrace.

See how our forms stack up with our Size Chart for a detailed comparison.

A step-by-step guide to how The Mug goes from a chunk of raw, regional clay to an heirloom-quality vessel you can use and adore for decades.

#TheMug In The Wild

One day, you’re a person who grabs the first coffee mug in the cabinet and the next, you’ve got an East Fork Mug now you’re forever fishing it out of the dishwasher. It’s simple, beautiful and then there’s how it feels in your hand, that little bit of heft.